In the rapidly evolving manufacturing industry, one technique that has gained significant attention is 2K injection molding. This innovative process allows for the creation of complex plastic parts with multiple materials or colors in a single production cycle. In this article, we will explore what exactly 2K injection molding entails and its impact on smart manufacturing.

Click to find more about what is 2k injection molding.

The Basics of 2K Injection Molding

2K injection molding, also known as two-shot or multi-shot molding, involves injecting two different materials into a mold to create a single part. The process typically utilizes an injection molding machine equipped with dual barrels and nozzles capable of injecting each material separately. By precisely controlling the sequence and timing of injections, manufacturers can achieve intricate designs and functional integration within a single component.

This technique offers numerous advantages over traditional methods. It eliminates the need for secondary assembly processes by directly integrating different materials or colors during production. Additionally, it enhances product durability by ensuring strong bonding between layers while reducing potential leakage points.

Find more about impact smart manufacturing.

The Impact on Smart Manufacturing

As industries embrace smart manufacturing practices to improve efficiency and productivity, 2K injection molding plays a crucial role in meeting these goals. By combining multiple functions into one part through this advanced technique, manufacturers can streamline their production processes significantly.

Furthermore, incorporating various functionalities within a single component reduces overall material consumption and waste generation. This not only contributes to environmental sustainability but also lowers costs associated with raw materials procurement and disposal.

The ability to produce complex parts with enhanced functionality using fewer resources positions companies utilizing 2K injection molding at an advantage in today’s competitive market landscape.

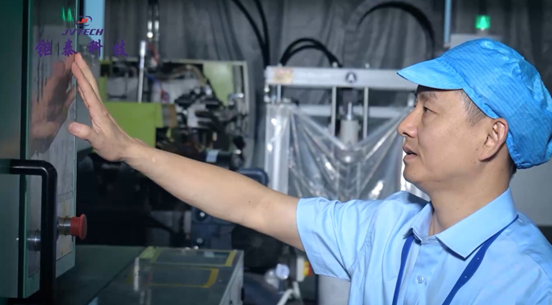

JVTECH: Pioneering Innovation in 2K Injection Molding

One notable player in the field of 2K injection molding is JVTECH, a leading manufacturer specializing in advanced plastic molding solutions. With their expertise and cutting-edge technology, JVTECH has revolutionized the industry by offering comprehensive services for complex part production.

By leveraging their state-of-the-art equipment and experienced engineers, JVTECH ensures precise control over material distribution and adherence during the 2K injection molding process. This results in high-quality parts with exceptional performance characteristics.

Moreover, JVTECH’s commitment to continuous improvement and customer satisfaction sets them apart from competitors. They collaborate closely with clients to understand their specific requirements and provide tailored solutions that balance features and simplicity effectively.

In Conclusion

2K injection molding is an innovative technique that allows for the creation of complex plastic parts with multiple materials or colors within a single production cycle. Its impact on smart manufacturing includes improved efficiency, reduced waste generation, and enhanced functionality while minimizing resource consumption. Companies like JVTECH are at the forefront of this technological advancement, delivering high-quality products through their expertise in 2K injection molding processes.